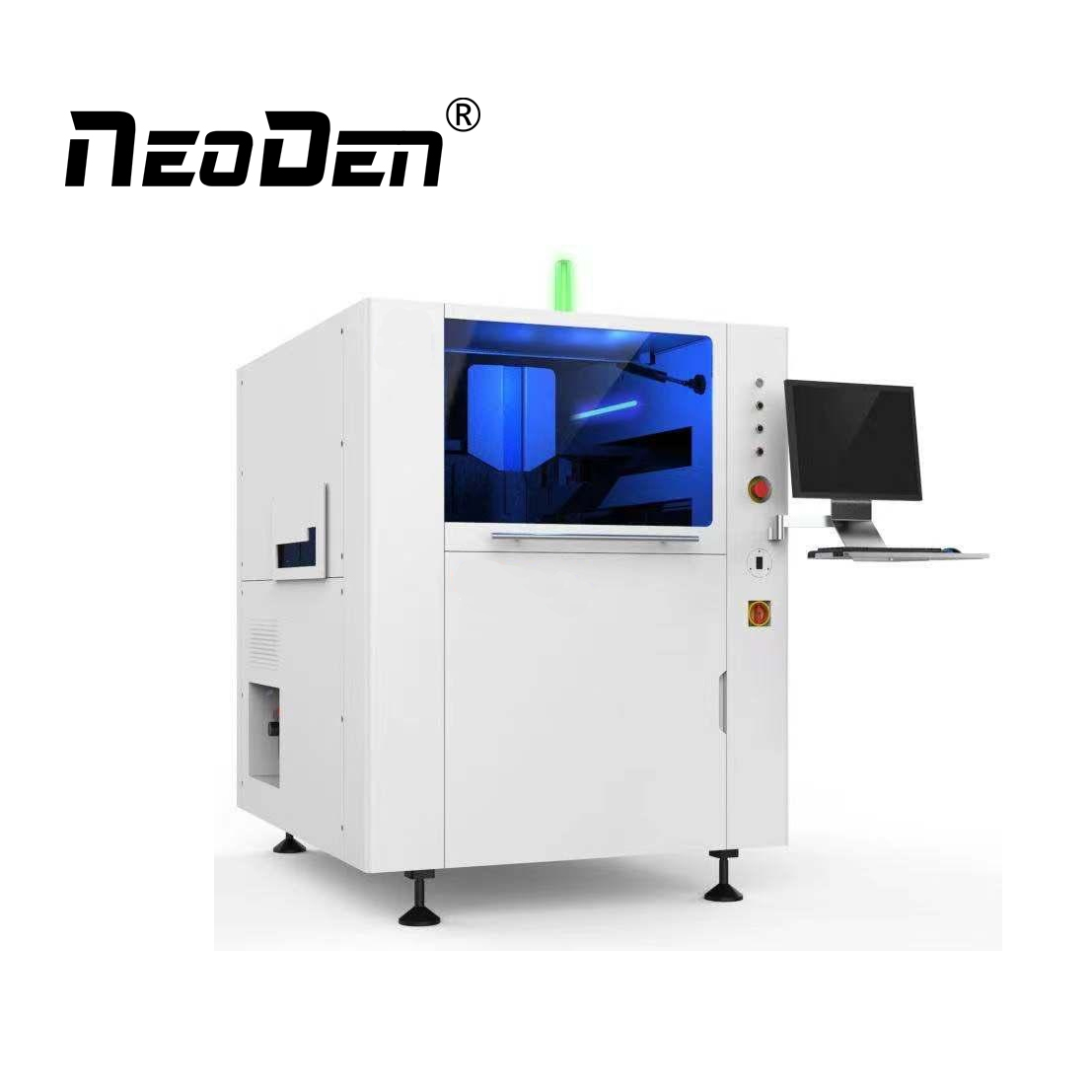

Tsis siv neeg Stencil tshuab luam ntawv

Tsis siv neeg Stencil tshuab luam ntawv

Specification

| Khoom npe | Tsis siv neeg Stencil tshuab luam ntawv |

| board loj (X x Y) | 450 x 350 mm |

| Yam tsawg kawg nkaus board loj (X x Y) | 50 mm x 50 mm |

| PCB thickness | 0.6 hli ~ 14mm |

| Warpage | ≤1% Diagonal |

| Qhov siab tshaj plaws board hnyav | 10 Kg |

| Board margin qhov sib txawv | Configuration rau 3mm |

| Qhov siab tshaj plaws hauv qab | 20 hli |

| Hloov ceev | 1500mm / s (Max) |

| Hloov qhov siab ntawm av | 900 ± 40mm |

| Hloov lub orbit kev taw qhia | LR, RL, LL, RR |

| Tshuab hnyav | Kwv yees li 1000Kg |

Feature

PCB clamp hom: Software adjustable siab ntawm elastic sab siab.

Kev xaiv

1. Zuag qhia tag nrho hauv qab suction chamber nqus tsev vacuum

2. Hauv qab multipoint ib nrab lub tshuab nqus tsev

3. Ntug xauv clamping phaj

Kev them nyiaj yug Board txoj kev sib nqus thimble, tshwj xeeb ua haujlwm tuav ntaus ntawv (xaiv: Grid-Lok)

Kev tswj kom zoo

Peb muaj QC tus neeg nyob hauv cov kab ntau lawm ua rau kev tshuaj xyuas.

Tag nrho cov khoom yuav tsum tau kuaj xyuas ua ntej xa khoom.Peb ua inline soj ntsuam thiab zaum kawg soj ntsuam.

1. Tag nrho cov khoom siv raw tau kuaj xyuas thaum nws tuaj txog peb lub Hoobkas.

2. Txhua daim thiab lub logo thiab tag nrho cov ntsiab lus tshawb xyuas thaum lub sijhawm tsim khoom.

3. Tag nrho cov ntsiab lus ntim tau kuaj xyuas thaum tsim khoom.

4. Tag nrho cov khoom tsim tau zoo thiab ntim tau kuaj xyuas qhov kawg tom qab ua tiav.

Muab ib-nres SMT sib dhos ntau lawm kab

Cov khoom muaj feem xyuam

Hais txog peb

Hoobkas

Tsim los ntawm 2010 nrog 100+ neeg ua haujlwm & 8000+ Sq.m.Hoobkas ntawm cov cuab yeej ywj pheej, kom ntseeg tau tus qauv kev tswj hwm thiab ua tiav cov txiaj ntsig kev lag luam zoo tshaj plaws thiab txuag tus nqi.

Muaj tus kheej lub chaw machining, txawj sib dhos, tester thiab QC engineers, los xyuas kom meej lub peev xwm muaj zog rau NeoDen tshuab tsim, zoo thiab xa.

Ib qho tshwj xeeb ntawm tag nrho cov tuam txhab hauv Suav teb uas tau tso npe thiab pom zoo CE los ntawm TUV NORD.

NeoDen muab kev pab cuam lub neej ntev thiab kev pabcuam rau txhua lub tshuab NeoDen, ntxiv rau, kev hloov kho software tsis tu ncua raws li kev siv cov kev paub dhau los thiab kev thov txhua hnub los ntawm cov neeg siv khoom.

Daim ntawv pov thawj

Exhibition

FAQ

Q1:Koj qhov kev pab cuam tom qab muag yog dab tsi?

A: Peb lub sijhawm lav zoo yog 2 xyoos.Txhua qhov teeb meem zoo yuav daws tau rau cov neeg siv khoom txaus siab.

Q2:Muaj pes tsawg tus neeg ua haujlwm hauv koj lub hoobkas?

A: Ntau tshaj 200 tus neeg ua haujlwm.

Q3:Lub sijhawm khoom xa tuaj rau ntau lawm yog dab tsi?

A: Txog 15-30 hnub.

Yog tias koj xav tau, thov hu rau peb kom paub ntau ntxiv.

Q1:Yam khoom koj muag?

A: Peb lub tuam txhab ua haujlwm hauv cov khoom hauv qab no:

Cov khoom siv SMT

SMT accessories: Feeders, Feeder qhov chaw

SMT nozzles, nozzle tu tshuab, nozzle lim

Q2:Thaum twg kuv tuaj yeem tau txais cov lus hais?

A: Peb feem ntau hais hauv 8 teev tom qab peb tau txais koj qhov kev nug.Yog tias koj ceev heev kom tau txais tus nqi, thov qhia rau peb kom peb yuav suav nrog koj qhov kev nug tseem ceeb.

Q3:Kuv tuaj yeem tuaj xyuas koj lub Hoobkas?

A: Los ntawm txhua txoj kev, peb zoo siab tos txais koj tuaj txog, Ua ntej koj tawm ntawm koj lub tebchaws, thov qhia rau peb paub.Peb yuav qhia koj txog txoj kev thiab npaj sijhawm tuaj tos koj yog tias ua tau.