1) Electroforming stencil

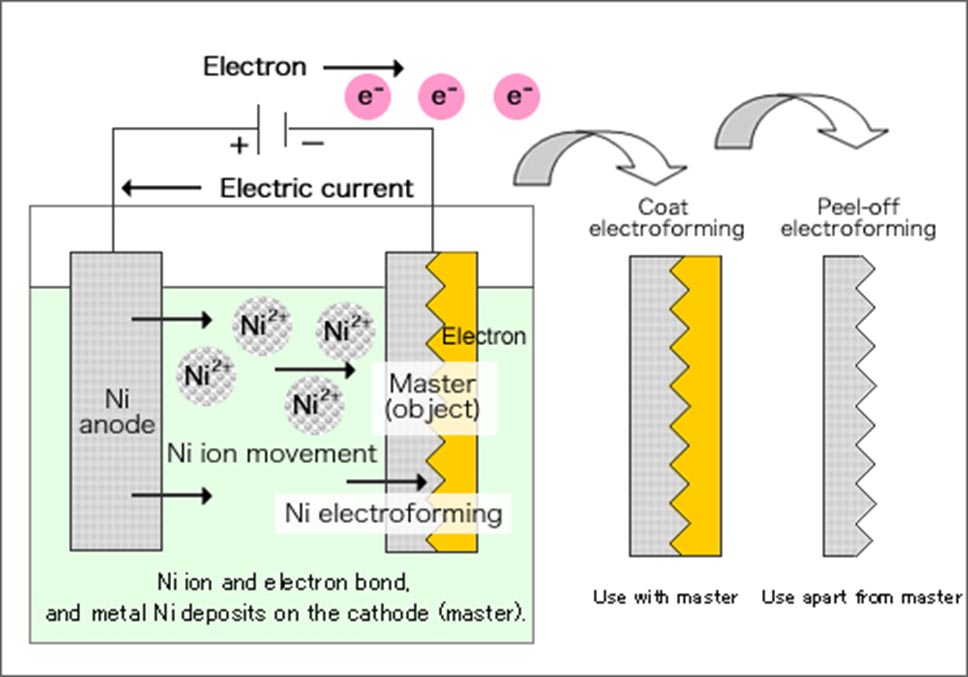

Lub hauv paus ntsiab lus ntawm cov electroformed stencil: lub electroformed template yog tsim los ntawm kev luam tawm cov khoom siv photoresist ntawm cov hlau conductive hlau phaj, thiab tom qab ntawd los ntawm cov pwm pwm thiab ultraviolet raug, thiab tom qab ntawd cov qauv nyias yog electroformed hauv cov kua electroforming.Qhov tseeb, electroforming zoo ib yam li electroplating, tshwj tsis yog tias daim ntawv npib tsib xee tom qab electroforming tuaj yeem raug stripped los ntawm cov phaj hauv qab los ua stencil.

Electroforming stencil muaj cov yam ntxwv hauv qab no: tsis muaj kev ntxhov siab hauv cov ntawv hlau, lub qhov phab ntsa yog du heev, cov stencil tuaj yeem yog cov tuab (hauv 0.2 hli, tswj los ntawm lub sijhawm electroforming), qhov tsis zoo yog tias tus nqi siab.Cov duab hauv qab no yog kev sib piv ntawm cov laser hlau mesh thiab electroformed steel mesh phab ntsa.Cov phab ntsa du ntawm lub electroformed steel mesh muaj qhov zoo dua demoulding nyhuv tom qab luam ntawv, yog li qhov qhib piv tau qis li 0.5.

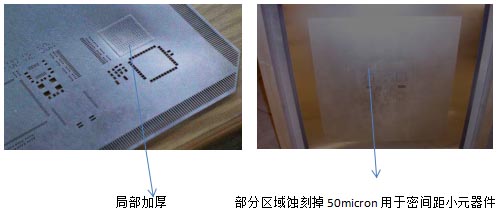

2) Ladder stencil

Cov kauj ruam steel mesh tuaj yeem ua rau hauv zos thickened lossis thinned.Ib feem ntawm cov thickened yog siv los luam cov ntaub qhwv uas yuav tsum tau muab tshuaj txhuam ntau ntau, thiab qhov tuab yog pom tau los ntawm electroforming, thiab tus nqi ntau dua.Lub thinning yog tiav los ntawm chemical etching.Lub thinned ib feem yog siv los luam cov ntaub qhwv ntawm cov khoom me me, uas ua rau cov nyhuv demolding zoo dua.Cov neeg siv uas raug nqi ntau dua raug pom zoo kom siv tshuaj etching, uas yog pheej yig dua.

3) Nano Ultra Txheej

Txheej los yog plating ib txheej ntawm nano-txheej txheej ntawm cov hlau mesh, nano-txheej txheej ua rau lub qhov phab ntsa tshem tawm cov tshuaj txhuam, yog li cov nyhuv demolding zoo dua, thiab qhov ntim stability ntawm solder paste printing yog zoo ib yam.Nyob rau hauv txoj kev no, qhov zoo ntawm kev luam ntawv yog ntau guaranteed, thiab tus naj npawb ntawm tu thiab so ntawm steel mesh kuj yuav txo tau.Tam sim no, feem ntau ntawm cov txheej txheem hauv tsev tsuas yog siv cov txheej txheej nano-txheej, thiab cov nyhuv tsis muaj zog tom qab qee qhov kev luam ntawv.Muaj cov nano-coatings ncaj qha plated ntawm cov hlau mesh, uas muaj cov nyhuv zoo dua thiab ua haujlwm ntev, thiab tau kawg tus nqi siab dua.

3. Ob chav solder paste molding txheej txheem.

1) Kev luam ntawv / luam ntawv

Ob lub tshuab luam ntawv yog siv los luam tawm thiab ua daim ntawv lo.Thawj tus siv cov stencil zoo tib yam los luam cov ntaub qhwv ntawm cov khoom me me nrog cov suab zoo, thiab tus thib ob siv 3D stencil los yog kauj ruam stencil los luam cov ntaub ntawm cov khoom loj.

Txoj kev no yuav tsum muaj ob lub tshuab luam ntawv, thiab tus nqi ntawm stencil kuj tseem siab.Yog tias siv 3D stencil, xav tau ib qho txhuam txhuam, uas ua rau tus nqi nce ntxiv thiab cov khoom siv tau qis dua.

2) Printing / tshuaj tsuag tin

Tus thawj solder paste tshuab luam ntawv luam tawm ze-pitch me me pads, thiab lub tshuab luam ntawv thib ob inkjet luam cov ntaub ntawv loj.Nyob rau hauv txoj kev no, cov tshuaj nplaum molding nyhuv yog qhov zoo, tab sis tus nqi siab thiab qhov ua tau zoo yog tsawg (nyob ntawm seb muaj pes tsawg leeg ntawm cov khoom siv loj).

Cov neeg siv tuaj yeem xaiv los siv cov kev daws teeb meem saum toj no raws li lawv tus kheej qhov xwm txheej.Nyob rau hauv cov nqe lus ntawm tus nqi thiab ntau lawm efficiency, txo lub thickness ntawm lub stencil, siv tsawg-yuav tsum tau aperture cheeb tsam piv stencils, thiab kauj ruam stencils yog ntau haum xaiv;cov neeg siv uas muaj cov zis tsawg, cov kev xav tau zoo, thiab cov neeg siv tsis muaj nqi tuaj yeem xaiv cov ntawv luam tawm / dav hlau luam ntawv.

Post lub sij hawm: Aug-07-2020